Why should you use Drain Traps and Drain gutters in Food Industry:

As food industry professionals, we know your number one priority is maintaining a clean and risk-free environment.

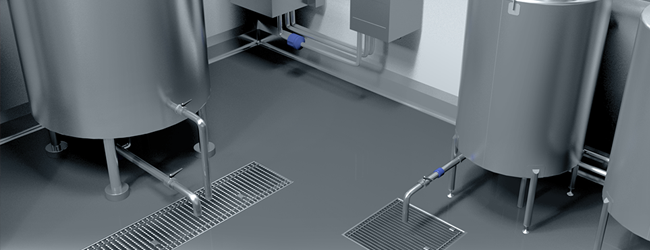

That's why we build drainage systems that are sanitary and safe - no matter how busy you get. Drains matter - they are the most used equipment in your facility. Drainage systems bear the brunt of constant traffic, experience non-stop usage, and have to stay clean, even on your busiest day.

We have made it our goal to be the solution to your drainage problem. How? With stainless-steel drains that stand up to the roughest wear, keep both your floor and your product bacteria-free, and above all are fast and easy to clean.

Hygiene (Food safety):

Medium and high-risk zones within food processing environments often necessitate additional hygiene considerations.

1. Stainless steel is an excellent material for use in areas where hygiene performance is paramount

2. In addition to the material properties of the stainless trench, ACO manufactures its trench drains and floor drains incorporating a hygienic design that allows easy cleaning and protection against microorganisms and bacteria

3. We apply relevant hygienic design principles reserved for food contact surfaces or recommended by NSF/ANSI and EHEDG Products shown with the symbol in the catalog indicating hygienic design in addition to the stainless steel hygienic properties.

Material Technology:

Stainless steel is the name given to a range of steels that have greatly enhanced corrosion resistance over conventional mild steels.

In the building and construction industry, stainless steel is selected due to

Why we use only Stainless steel:

· Excellent strength and resistance to oxidation at high temperatures

· Durability and corrosion resistance in highly aggressive environments

· Hygienic and easily cleaned surfaces

· Aesthetically attractive surface finishes

·Non-magnetic properties (working the material can introduce some magnetic properties) these features make stainless steel an obvious choice for demanding drainage applications

Types of Applications:

· Dairy Facilities

· Slaughter Houses

· Processing Plants

· Brewery/Winery

Dairy Facilitates:

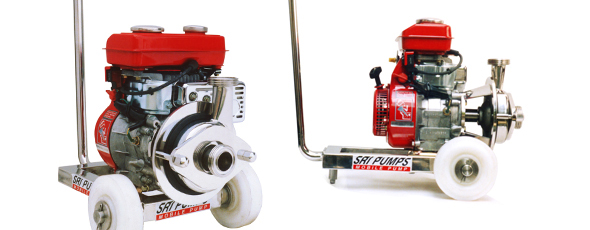

A drain trap is part of the plumbing system which retains a small amount of water or any other liquid every time the sink drains its content. The collected liquid in the curved part of the trap bottom seals the Gully and keeps cesspool gases coming back through the trap and entering the premises. Traps are chiefly used in the drainage system in Dairy, Dairy Allied Industries, and laboratories.

Drain Trap is made of superior grade stainless steel which is resistant to corrosion, chemical abrasion and is designed and made to trap waste granules at different levels of the Gully trap.

Processing plants:

Integrated drainage systems are designed to protect your business and the environment. Our aim is to constantly improve every aspect of safety, hygiene, and functional performance. We believe our systems and services are truly unique, delivering unparalleled benefits to everyone involved in project delivery or subsequent operation.

Wastewater can contain fat which is a major cause of pipe blockages and cannot be released into the wastewater system. The drainage system installed in food operations should not compromise its cleanability, durability, and flow rate not to affect food safety, operational cost, and health & safety.

Types:

Food Safe Slot Drains:

Our Safe slot drains are an easy-to-clean product. Designed for the highest-regulated food processing facilities, this heavy-duty load-bearing drainage system offers our smoothest design ever for complete drainage sanitation. Constructed from T304 or T316 stainless steel, this drainage system is efficient to clean, making the maintenance of a hygienic production area a breeze.

Food Safe Area Drains:

The Food Safe Area Drain is radiuses stainless steel drainage system designed to eliminate standing water easily and hygienically. It is specially designed to reduce odor, regardless of how busy the operation is. Our special 'Tamperproof' strainer ensures that only authorized personnel have full access to the system, ensuring your facility remains both safe and secure.

Food Safe Trench Drain:

Our Food Safe Trench Drain is your go-to when it comes to removing solids from a production area, without fear of a clogged drain. Constructed from stainless steel, this option provides full access to the drainage channel, while the floor-level grating provides a safe, trip-free working space. 'Tamper-Proof' locks on the grates ensure employee safety and company security.

Features:

All stainless steel traps to be installed In pipe ends. Automatically drains Condensate from the air and inert gas systems.

1. Constant water seal and unique rotational seating design eliminate concentrated wear to ensure long life.

2. Three-point seating provides a tight seal even under no-load conditions (with rubber orifice).

3. Precision ground float ensures superior Sealing.

4. Built-in screen with large surface area ensures extended trouble-free operation.

5. Self-modulating free float provides continuous, smooth, low-velocity condensate discharge as process loads vary.

Comments

Post a Comment