Revolutionizing Fluid Dynamics: The History, Innovation, and Working Mechanism of Engine Coupled Pumps by Sri Pumps and Fittings Industrial Corporation

Introduction:

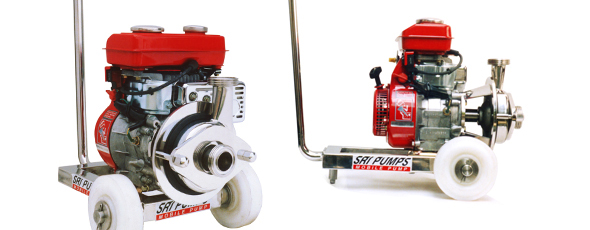

Engine Coupled Pumps, popularly known as Mobile Pumps, have transformed the landscape of fluid transfer solutions, providing portable and versatile options for various industries. Among the pioneers in this field, Sri Pumps and Fittings Industrial Corporation have played a crucial role in shaping the history and advancing the working mechanisms of Engine Coupled Pumps.

Evolution of Engine Coupled Pumps:

The early 20th century saw the inception of mobile pumps, addressing the need for portable pumping solutions in sectors such as firefighting, construction, and agriculture. The initial models were cumbersome and limited in terms of mobility. The turning point came with the integration of engines, marking the shift towards Engine Coupled Pumps and unlocking new possibilities for efficiency and flexibility.

Working Mechanism: Prime Mover - Engine Integration:

The heart of Engine Coupled Pumps lies in the integration of an internal combustion engine, typically fueled by gasoline or diesel. This engine serves as the prime mover, converting fuel energy into mechanical power.

Transmission of Power:

The mechanical power generated by the engine is then transmitted to the pump through a coupling mechanism. This connection ensures a synchronized operation between the engine and the pump, allowing for seamless power transfer.

Pump Mechanism:

The pump itself consists of an impeller or a rotor, which is responsible for generating the flow within the system. As the impeller rotates, it creates a low-pressure zone, drawing fluid into the pump. The fluid is then propelled through the pump, gaining velocity and pressure.

Fluid Discharge:

The pressurized fluid is expelled through an outlet, directed towards the intended destination. This mechanism allows for efficient fluid transfer over varying distances and elevations.

Control Systems:

Modern Engine Coupled Pumps, particularly those by Sri Pumps and Fittings Industrial Corporation, often incorporate advanced control systems. These systems enable operators to monitor and regulate pump performance remotely, optimizing efficiency and responding to changing operational requirements.

Sri Pumps and Fittings Industrial Corporation's Technological Advancements:

Variable Speed Control:

Sri Pumps and Fittings Industrial Corporation have introduced variable speed control features, allowing operators to adjust the pump's speed based on demand. This not only enhances efficiency but also prolongs the lifespan of the equipment.

Anti-Cavitation Measures:

Cavitation, a common issue in pump systems, can lead to damage and reduced efficiency. Sri Pumps and Fittings Industrial Corporation have implemented anti-cavitation measures, ensuring smooth and reliable pump operation.

Smart Sensors and Monitoring:

Integration of smart sensors and monitoring systems enables real-time data collection. Operators can receive alerts for potential issues, facilitating proactive maintenance and minimizing downtime.

Applications Across Industries:

The versatile working mechanism of Engine Coupled Pumps has found applications in diverse industries:

- Agriculture: For irrigation and water transfer.

- Construction: Efficient dewatering and concrete pumping.

- Oil and Gas: Handling fluid transfer in exploration and extraction processes.

- Emergency Response: Providing critical water supply during firefighting or disaster relief efforts.

Conclusion:

Engine Coupled Pumps have come a long way since their inception, and Sri Pumps and Fittings Industrial Corporation have been instrumental in driving innovation within this space. The sophisticated working mechanisms and technological advancements introduced by Sri Pumps and Fittings Industrial Corporation continue to redefine the standards of efficiency, reliability, and environmental sustainability in fluid transfer solutions. As industries evolve, the journey of Engine Coupled Pumps is far from over, with Sri Pumps and Fittings Industrial Corporation leading the way in shaping the future of mobile pump technologies.

Comments

Post a Comment