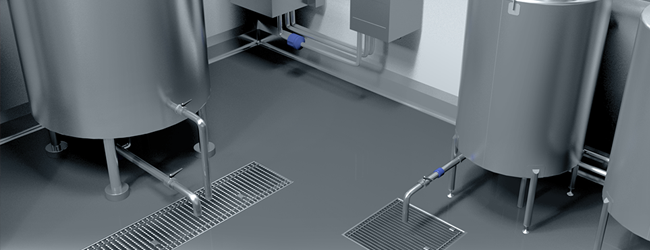

Why should you use Drain Traps and Drain gutters in Food Industry: As food industry professionals, we know your number one priority is maintaining a clean and risk-free environment. That's why we build drainage systems that are sanitary and safe - no matter how busy you get. Drains matter - they are the most used equipment in your facility. Drainage systems bear the brunt of constant traffic, experience non-stop usage, and have to stay clean, even on your busiest day. We have made it our goal to be the solution to your drainage problem. How? With stainless-steel drains that stand up to the roughest wear, keep both your floor and your product bacteria-free, and above all are fast and easy to clean. Hygiene (Food safety): Medium and high-risk zones within food processing environments often necessitate additional hygiene considerations. 1. Stainless steel is an excellent material for use in areas where hygiene performance is paramount 2. In addition to the material properties of the s